Turbine Oil Systems

IFS was once tasked with replacing a 50 year old DeLaval dairy centrifuge processing turbine oil with a modern Alfa Laval MAB-102 centrifuge improved efficiency. It also allowed the turbine operator to breathe easier knowing service and spare parts and now available. The centrifuge was worn out and obsolete. It had started life as a hand cranked dairy separator and was converted for processing turbine oil in the 40s. A washing machine motor replaced the hand crank and for the next 50 years life was good. This changed in 1995 when the machine simply wore out. Replacement parts were not available and it was time for a new machine

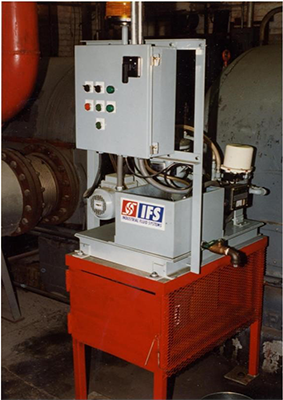

Industrial Fluid Systems was contracted to build a new centrifuge system that would replace the old one. A conversion package was engineered and built to fit into the existing work envelope of the old machine. Automated valves and updated controls were supplied and the system was back in operation. Based on the success of the project a sister plant ordered a replacement for their machine 2 years later.

System Requirements

- Replace the 50 year old DeLaval milk separator converted to turbine oil

- Provide a small package that would fit in the same work area

- Remove all free water and solids down to 5 microns

- Operate on 220 VAC 3ph power

Equipment Provided

- Alfa Laval MAB-102 high speed disc centrifuge

- Engineered base to fit existing table

- Automated feed valve

- NEMA 12 Rated Control Panel with Disconnect and Stop/Start controls

- Special tools for servicing the centrifuge

- Complete Documentation with Spare Parts List

- Runoff & Training at the Customer Plant