Rock Valley Oil and Chemical Distributors

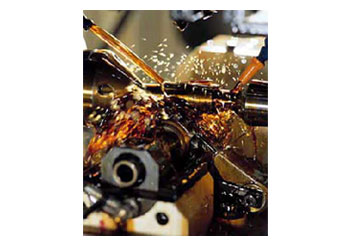

Industrial Fluid Systems is an authorized distributor of Rock Valley Oil and Chemical products. Rock Valley has been manufacturing cutting oils, lubricants, rust inhibitors, and specialty metalworking fluids since 1971. Whether it is standard specification or custom blended lubricants, we have the industrial fluid products and expertise you are looking for. We can recommend and provide you with the appropriate oil or fluid for your unique application.

We offer our industrial fluid customers quality products backed up with excellent service at a competitive, affordable price. Our long- time customers know this to be true. Our product line is also “user and environmentally friendly, as well as green technology”. New customers soon realize we live up to our promise of quality, service, and price.

Some of our Rock Valley products

- air compressor oils

- cleaners

- coolants

- corrosion preventatives

- drawing & forming oils

- honing oils

- hydraulic fluids

- industrial lubricants

- metal forming / stamping fluids

- metalworking fluids

- process oils

- quench & cutting oils

- reference oils

- rust preventives

- way oils

-

Rock Valley 4465 Concentrate

4465 is a water dilutable drawing compound and blank washing compound formulated to provide superior lubricity and corrosion protection in blank washing operations.

-

Rock Valley 4465-XHD

Chempet 4465-XHD is a water dilutable heavy-duty drawing compound formulated to provide superior lubricity and corrosion protection for deep drawing automotive parts.

-

7723C Oil Blank Wash

7723C Oil Blank Wash is a drawing and stamping fluid formulated to provide excellent formability of galvanized body panels as well as all other types of substrates used in automotive car body production including aluminum.

-

EP Gear Lube S Series

Rock Valley EP Gear Lubricants are advanced-formula products intended for severe industrial applications. They are high-quality base stocks fortified with extreme pressure additives which meet the performance requirements of U.S. Steel 224 and AGMA 250.04 specifications.

-

Progrind 600 AS LV

Progrind 600 AS LV is mineral oil fortified with additives to provide improved lubricity and wetting properties. This product is excellent for use with non-ferrous metals to provide EP, cooling and lubrication in honing and grinding operations and other metal removal operations especially tool grinding.

-

Progrind 632

Progrind 632 is a low viscosity blend of non-chlorinated extreme pressure and lubricity additives. It has been specially formulated to provide longer wheel life, better finish, and high production rates.

-

Progrind 637

Progrind 637 is carefully blended to provide longer wheel life, better finish, and high production rates.

-

Progrind 639

Progrind 639 is a low viscosity blend of non-chlorinated extreme pressure and lubricity additives. It has been specially formulated to provide longer wheel life, better finish, and high production rates.

-

Quench Oil 1080

Quench Oil 1080 is a fast quench oil designed to impart maximum hardness values to low carbon and low alloy steels.

-

Quench Oil 1080 Very Fast

Quench Oil 1080 Very Fast is a very fast quench oil designed to impart maximum hardness values to low carbon and low alloy steels.

-

QUENCH OIL 1070

Quench Oil 1070 is a fast quench oil designed to impart high hardness values to low carbon-low alloy steels, while giving long life and clean parts.

-

Rockcut 108 (Vanishing Oil)

A light-bodied, solvent based fluid formulated to provide lubricity on mild metal forming and stamping operations both ferrous and non-ferrous.

-

Rockcut 262 IS HVF

Rockcut 262 IS HVF is a blend of vegetable and mineral oil, used cold heading extrusion product that offers a high degree of chemical activity to provide outstanding forming of tough, ductile metals; while maintaining good tool life and surface finish.

-

Rockspin Oils

Rockspin Oils are high quality spindle oils manufactured from selected stock oils compounded with film strength and lubricity improvers, anti-wear, oxidation and rust/corrosion inhibitors.

-

Trojan AW Series

Trojan AW (Anti-Wear Hydraulic Oils) have been developed to meet the demanding requirements of today’s high-pressure, high-output pumps and hydraulic systems. Excellent thin oil film protection is provided to protect pump vanes, pistons, control valves, and actuators found in industrial, marine, or mobile applications.

-

Val-Rust WD & Val-Rust WD High Flash

A light, oily film-type rust preventive, Val-Rust WD & Val-Rust WD High Flash find many applications for short-term protection against corrosion, on in-process and interplant metal components, both ferrous and non-ferrous.

-

Viscool 5126

A low to moderate duty soluble oil type coolant formulated for a wide variety of metalworking operations including machining and grinding operations on both ferrous and most non-ferrous metals.

-

Viscool 5505

Formulated for a wide variety of machining and grinding operations on both ferrous and most non-ferrous metals. This unique combination of ingredients forms a completely stable emulsion providing exceptional tool life and long term trouble free performance.

-

Viscool 5505 BC

Formulated for a wide variety of machining and grinding operations on both ferrous and most non-ferrous metals. This unique combination of ingredients forms a completely stable emulsion providing exceptional tool life and long term trouble free performance.

-

Viscool 6325 N

Formulated for a wide variety of metalworking operations including machining and grinding operations on both ferrous and most non-ferrous metals.

-

Viscool 6325 OC

Formulated for a wide variety of metalworking operations including machining and grinding operations on both ferrous and most non-ferrous metals. The unique combination of ingredients forms a stable emulsion even in extremely hard water and provides exceptional metal working ability, tool life and long term trouble free performance.

-

Viscool 7332

A non-nitrite, synthetic machining and grinding fluid. It is recommended for high speed, heavy-duty applications where maximum sump life, extended tool life and rust protection are the primary requirements.

-

Viscool 7335 C

A non-nitrite, synthetic machining and grinding fluid. It is recommended for high speed, heavy-duty applications where maximum sump life, extended tool life and rust protection are the primary requirements.

-

Visform 3200

A semi-synthetic blend of non-chlorinated extreme pressure and high lubricity additives. The versatility of Visform 3200 allows it to be used in multiple applications such as drawing, piercing and punching of ferrous and non-ferrous metals.