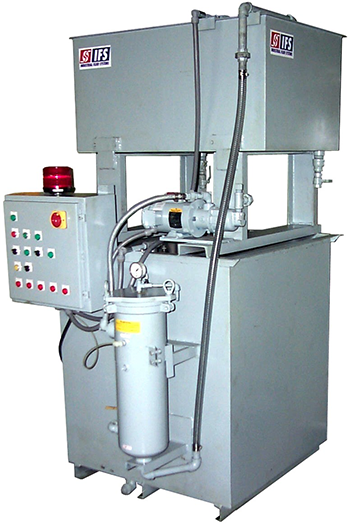

Coolant Recycling System CRS-300 reduces chemical cost and waste hauling by 50%

Recycling 200 gallons/day of used machine tool coolant would significantly reduce waste hauling and the purchase of coolant chemistry. The system requirements were simple. A turnkey system easy to operate with minimum maintenance. Operators collect used coolant with a sump sucker and pump it into the recycler. A coolant transfer cart with 55 gallon drum is used to transfer recycled coolant back to a machine.

After reviewing the application and coolant being used it was determined that an oil/water separator would remove the tramp oil. Solid loading was not high so a single bag filter would be adequate to recycle 4 to 5 batches of coolant. Based on this information, the SSM-300 was a perfect solution. Industrial Fluid Systems – CRS-300 – PDF

System Requirements

- Recycle 200 gallons/day of coolant

- Remove tramp oil

- Filter out solids

- Operate on 120 volts AC

- Collect tramp oil in drum

- Monitor Fluid Levels;

- Low Level Sensor

- Full Level Sensor

- Overflow Sensor w/ Alarm

- Tram oil full sensor

- Clean fluid transfer pump

Equipment Specifications

- 300 Gallon process tank

- 5 GPM Tramp oil separator

- 15 gpm Feed/Transfer pump

- Bag filter w/15 micron bags

- 120 VAC 1Ph power

- Multi-machine Sensors

- Low Level Sensor

- Add Fluid Sensor

- Overflow sensor w/Alarm

- Continuous or Timed Cycle

- Bag Filter Assembly

- Tramp oil drum w/full sensor

- AutoCAD system layout

- Electronic documentation